Pig raising equipment FAQ

Q: The light wire trips

Answer: 1 Check whether the leakage protection switch is burned out. 2. Close the switch in sections and check which section has tripped 3. After sectioning, check the one section by section

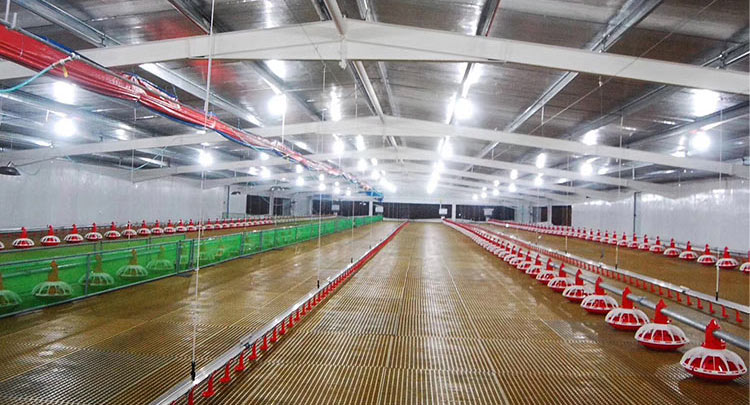

Question: The reel material line and the chain material line chain cannot be pulled

Answer: 1. Look at the tightness of the strip 2. Look at whether there is any foreign matter stuck in the corner.

1. Detection method of power regulator:

1) Connect the load bulb to terminals M1 and M2, and connect the power cord to terminals L and N. 2) Power-on test, automatically observe whether the brightness of the tungsten filament lamp and the voltage at the terminals L and N change with the change of 0-10V. 3) Power-on test, manually observe whether the brightness of the tungsten filament lamp and the voltage at the terminals L and N change with the rotation of the knob.

2. How to judge whether the circuit breaker is faulty

1). Multimeter quick identification method: press the red button of the thermal relay, use the path file to measure a pair of opposite normally open points in and out, the normally closed point shows infinity, indicating that the circuit breaker is good. 2). Press the green button of the thermal relay, place the multimeter on the test path block, measure a pair of opposite normally open points in and out of the wire, if it emits a beep and has a fixed resistance, it means that the circuit breaker is good of. 3). When the load current exceeds the rated current of the motor protection circuit breaker, it will be automatically disconnected, so that the load contactor coil will be disconnected to protect the load! That the circuit breaker is good.

3. How to deal with the loose fan belt

1) Press the belt with your hand to move more than 1.5 cm inward to loosen (add a measuring arrow here) 2) Remove the belt, loosen the fastening bolt on the back with a wrench, and move the tensioner in a natural state to the original position. Hour hand rotation angle. (20°/40°/60°) 3) Press the belt again, press the belt to sense the tightness, and move 1.5 cm to the inside.

4, the chain breaks

Preliminary judgment of the broken position of the chain and determine the broken position. Then adjust the chain to the joint between the pipe and the pipe at the joint of the slipknot connection chain to break, and connect the chain with a slipknot (if conditions permit welding at the opening of the slipknot), butt the material pipe and restore the corner to the previous state.

5. The circuit breaker often turns off the motor (motor overload)

Insufficient power supply, check whether the phase is missing or the power conductor section is too small. The motor must provide a 3-phase 380 volt. Check whether it is connected to a 2-phase power supply. If there is debris in the chain, the motor starts abnormally. Check the material box, control material tray and unloading place, and remove the sundries.

6, the material line cannot be started

There is no power or the voltage is too low, if the fuse is burned out, replace the fuse; check whether the leakage protector is set correctly, under normal circumstances, the leakage protector will automatically cut off the motor power supply if the current is too high; check whether the main circuit meets the requirements for use.

7. How to deal with the alarm of the environmental controller?

directly press the number "6" key to find out the fault code, and find out the reason according to the code. 1——Low temperature alarm 2——High temperature alarm 3——Environment controller memory error alarm 4——All sensors have no signal 5——One sensor has no signal 6——Humidity alarm

8. What should I do if there is no display after the environment controller is powered on?

Check whether the power wiring is loose, and re-wire if loose; check whether the fuse and varistor are damaged, if damaged, replace the fuse (500mA) and varistor (14D471K).

9. What should I do if the material line is running without feeding?

Check whether there is no feed in the feed tower, if there is no feed, add feed; check whether the auger is broken, if there is a broken welding. Check whether the level indicator is faulty, replace the level indicator.

10. How to deal with the excessive current of the fan motor or the excessive temperature rise?

Adjust the voltage, power off to eliminate circuit problems; adjust the position of the motor to reduce the belt tightness; disassemble the motor to dry or replace it; increase the rotation time.

Mobile station

Mobile station WeChat

WeChat